Battery c - net, June 11 (xiao ho reports from Beijing) recently, successive power battery enterprises offering a "black" science and technology, Beijing who blue new energy technology co., LTD. (hereinafter referred to as: who blue new energy), general manager of yu will root pointed out that in the future there are two main battery performance improvement direction: the direction of high energy density and high power density. Car power batteries tend to be more energy-dense, and all the "dark tech" will be aimed at both directions, or both. In Yu Huigen's opinion, black technology can only become a disruptive technology when it is used. At present, there are many concepts of black technology, but fewer technologies can compete with liquid lithium-ion batteries.

On June 10th, Yu Qingjiao, Secretary General of Zhongguancun New Battery Technology Innovation Alliance and Chairman of the Battery 100 Association, made a special trip to investigate Weilan New Energy, and had a discussion with Yu Huigen, Chairman and General Manager of Weilan New Energy, Li Guogang and Xiang Jin, Vice General Manager of Weilan New Energy, and Deng Lin, Senior Financial Director.

Data show that Welion New Energy was founded in 2016, headquartered in Beijing, has two production bases in Beijing Fangshan and Jiangsu Liyang, with a total investment of more than 300 million yuan. According to Yu, the company is conducting research and development in the fields of automotive power batteries, 3C consumer batteries, UAV batteries and energy storage batteries.

Among them, in the field of UAV battery, the company will mass produce UAV battery in Liyang in July 2020. The production capacity is designed to be 200 million Wh, and the production capacity can be 5C continuous discharge 270Wh/kg mixed solid-liquid battery. At the same time, there will be a small amount of collinear production of automobile power battery.

In the field of energy storage batteries, the company has also done some research and development work. Based on the lithium iron phosphate battery, the company has further improved the safety and optimized the cycle life design, hoping to make the battery truly inherently safe.

In the field of automotive power batteries, the company has completed the design and development of hybrid solid-state batteries with high nickel ternary positive electrodes of more than 300Wh/kg. The company has sent samples to many international and domestic OECs for testing, and the evaluation results are good. The company has successfully passed needling, extrusion, overcharge, short circuit and other abuse tests, and the cycle life has reached more than 1200 times. According to the 18-24 months of OEMs' lead-in cycle, the product is expected to be mass-produced in 2022, and it will be adjusted in real time according to the market and capital situation in the later stage.

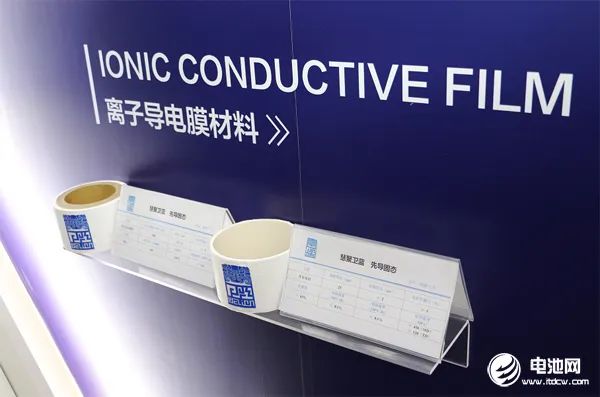

Yu Huigen said that the solid state battery of Weilan New Energy adopts oxide solid electrolyte + in-situ solid state technology. Considering the technological route of the process, the company hopes that the solid state battery can be mass-produced from the design stage and most of them can be compatible with existing equipment. At present, the development of the supply chain such as composite metal lithium, solid electrolyte and ionic conductive film is more focused on the development of new equipment. At present, the cost is relatively high because the quantity has not been produced yet. However, once it is mature and large-scale production is realized, the cost can be basically equal to or even lower than the existing liquid battery.

It is reported, Welion new energy on the basis of creating core technology platform, completed the in situ solid-state technology and atomic bonding technology, composite metal lithium technology, solid electrolyte, ionic conductive membrane technology, three-dimensional fluid technology, such as research, achieved 270 wh/kg uavs battery production, 300 wh/kg, 400 wh/kg battery power battery C sample, A sample of 500 wh/kg for the development of principle prototype.

In terms of scientific research investment, Welion New Energy currently has more than 260 staff and more than 130 research and development personnel. In the next 10 years, the company will ensure that 20-30% of the annual revenue will be invested in research and development, through continuous technological innovation, to build a moat with international competitors.

In terms of patents, Welion New Energy has applied for more than 100 national patents, of which 6 have been authorized, involving core materials and technologies such as solid-state battery composite cathode, solid-state electrolyte, diaphragm and negative electrode. In 2018, the company won the national high-tech and village high-tech certification, and was also a special prize project of scientific and technological achievements transformation of the Academy of Sciences.

It is worth noting that on March 29 last year, Jiangsu Weylan New Energy Battery Co., Ltd. held a grand foundation laying ceremony for the first-phase solid-state battery project. The total investment of the project was 500 million yuan, and the first-phase investment was 180 million yuan. After completion, it is expected to form an annual production scale of 100 million watt-hours solid-state battery. "Due to the impact of the epidemic, the company's project in Liyang has been delayed for one and a half months, mainly due to the supplier's equipment. It is expected to be put into production before the end of July 2020," Yu said.

From 2017 to 2019, Weilan New Energy has mastered the engineering process of in-situ solid state, preliminarily completed the core technology system and formed the intellectual property system. Yu Huigen revealed that the company will promote all key materials to achieve mass production in 2020-2022; Key equipment independent research and development, forming the overall solution; GWH automation production line put into operation. From 2023 to 2025, it is planned to realize the large-scale application of products in high-end 3C and high-end power fields; Master digital factory technology. After 2026, the series of products with advanced technology and technical economy will be promoted. Become the industry standard and benchmark enterprise, enter the mainstream field.