In September 2020, by the tianmu lake institute of advanced energy storage technology and Siemens industry software (Shanghai) co., LTD., jointly organized, liyang deepwater technology consulting co., LTD., liyang city people's government, the zhongguancun science and technology industrial park, jiangsu, Yangtze river delta physics, institute of physics, Chinese Academy of Sciences research center, "science and technology of energy storage magazine co-host of the first session of the national advanced intelligent power battery manufacturing and design meeting in jiangsu liyang! Mr. Li Yongwei, General Manager of Jiangsu Weilan New Energy Battery Co., Ltd., gave a keynote speech on "Demand Forecast for Intelligent Manufacturing from the Development of Solid State Battery Industry".

Mr. Li Yongwei, General Manager of Jiangsu Welion New Energy Battery Co., Ltd. : Good afternoon, everyone. Just now Mr. Fang Zhigang introduced the supporting role of software informatization and intelligentization for battery industry, new energy vehicle industry and other industries. In this report, I will forecast the industry's demand for intelligent manufacturing from battery research and development, manufacturing and customer service, and share with you what kind of demand there will be. I will briefly share them from three aspects. The first part is to introduce the development prospects of each battery technology and industry, and what kind of problems they will face. Then, the second part will cover the solid state battery, including key materials, cell and module design and manufacture, and what problems we need to solve. The third aspect will introduce the requirements of technology and industrial development for intelligent manufacturing.

I think there are probably quite a few of us present here who have experienced the development of a lithium battery industry for nearly 20 years. Twenty years ago, this was a very small industry. In terms of battery energy density, nickel metal hydride batteries might be 50-70Wh/Kg. So later on from lithium manganate, lithium iron phosphate to ternary materials, high nickel ternary materials such a material system change. The industry has grown from billions to tens of billions to hundreds of billions, and will soon become a trillion-dollar industry, and may even have more room to grow. This industry will provide a lot of space for our entire advanced battery technology development and industry development. However, with the improvement of battery energy density, safety issues are becoming more and more prominent, especially in energy storage, power batteries and new energy vehicles. So how to solve this problem, solid state battery to improve the safety of the battery, and continuously improve the energy density of the battery provides a good technical solution. The most important is to replace some or all of the liquid electrolyte with a solid electrolyte, which can further improve its safety, increase energy density through the introduction of lithium metal anode, and achieve long life performance through other battery design and system matching. In the short term, liquid batteries can continuously improve the performance of batteries through material modification, chemical formation, system matching and structural design. But to ultimately address battery safety issues and achieve higher energy density levels, solid-state batteries can provide a better solution by providing a higher voltage range, suppressing lithium side reactions, and broadening the temperature window. In the medium to long term, there is a lot of room for solid-state battery development.

Throughout the world, China, South Korea and Japan are relatively in the leading position of research and development and industrial application in this field. At the same time, many companies in Europe and the United States have now begun to lay out and build core technologies. The technology competition of solid state battery is becoming more and more fierce, especially with the international large automobile companies in the full involvement in this field, this process will play a greater role in promoting the development of the solid state battery industry. From the current overall development of the industry, the development and change of solid state battery, whether polymer solid state battery, thin film solid state battery, or sulfide solid state battery and oxide solid state battery, there are still various problems, still need to be further solved. From the perspective of deepening, the energy density can reach above 350Wh/Kg, the safety performance can reach Eurocar level 2, fast charging, long life, low cost, wide temperature range, and there is still a lot of work to be done in terms of related technology development and corresponding process development and industrial application.

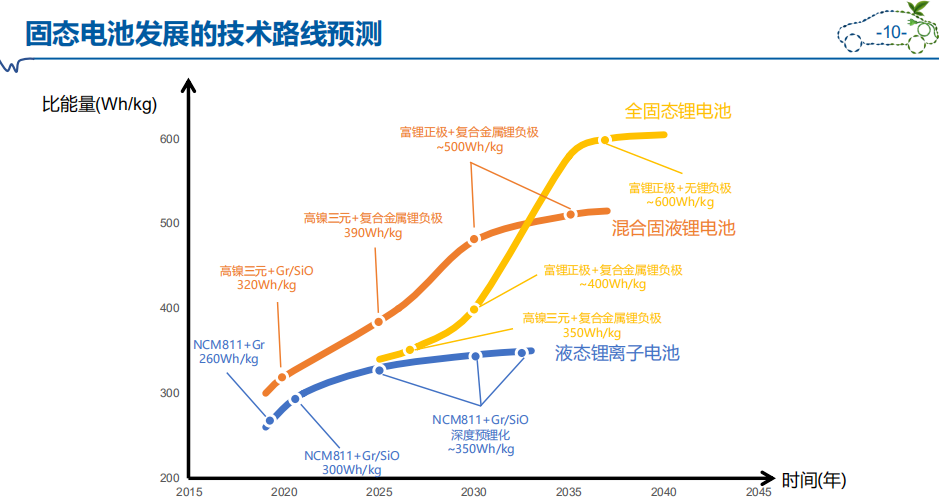

This is our prediction of where solid-state and liquid batteries will go. In the near term, there is room for 350Wh/Kg for liquid batteries. Over time, say 2022 or 2023, solid-liquid hybrid batteries will increase in energy density with different material systems. By 2025, all-solid-state batteries are expected to evolve from small consumer batteries to medium and large batteries, eventually reaching energy densities of 500-600Wh/Kg. For solid-state batteries, from the perspective of mass production, there are still some key technical and industrial problems that have not been well solved. This includes the key issues of basic science of interface, including material and cell structure efficiency issues, as well as the performance still need to be integrated optimization. At the same time, there is still no perfect industrial foundation to support the faster development of this industry. In order to achieve mass production, there is a lot of work to be done, from design, from development validation to mass production.

大概在2022年左右,随着在消费电池领域已经逐步导入和应用混合固液电池,动力和储能领域也将逐步导入固液混合电池。这里更多体现的是安全性上的快速提升。全固态电池也会按照这样的路径发展,预计2023年到2024年左右消费类电池会导入全固态电池,而动力和储能领域会随之跟进到产业化的程度。

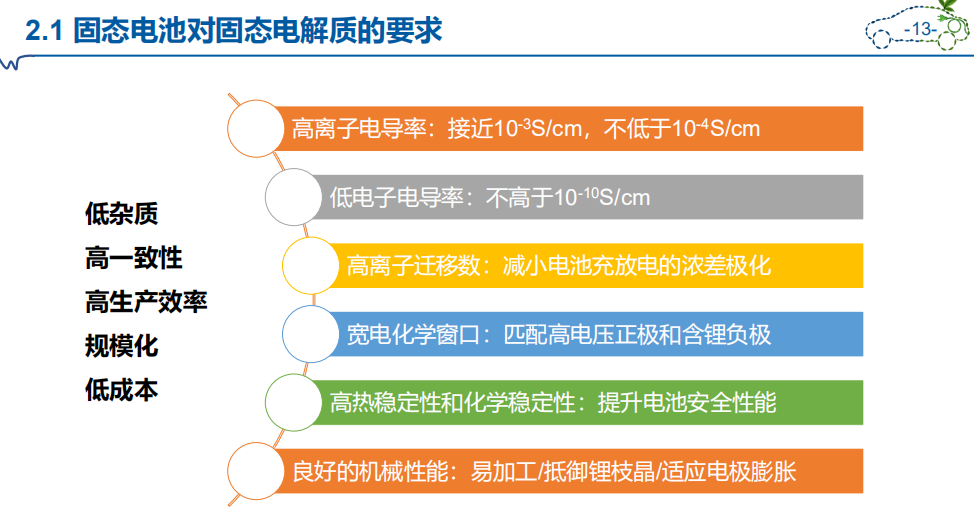

要做好一个电池,实际上受到多个层面因素的影响,我想大家都有非常深刻的体会。首先,关键材料能不能为电池提供比较稳定的性能,材料制备后能不能设计比较好的结构,把材料集成到电池里面。如何通过工业化的生产工艺来支撑。从材料发展来讲,经过这20多年,人们对材料已经有比较深刻的认知。对于关键材料的性能,比如固态电解质,包括离子电导率,电子电导率,离子迁移数,宽电化学窗口,热稳定性和化学稳定性,以及抑制锂枝晶生长所必需的良好的机械性能。

从制程来讲,要控制比较低的杂质含量,高度的一致性,一致性要通过全流程的过程质量控制,从配料和加工到最后的质量控制,整个流程要建立严格的过程质量标准,以达到最后的控制标准,同时形成规模化和低成本。经过2019和2020年的调整,整个动力电池行业已经向着大规模高集成度的方向发展。固态电池的发展会经过早期的低水平竞争,比较顺利地进入规范发展的阶段。各个体系的材料有对应的要求,其中既有优点也有缺点。固态电池不一定是单一的一种材料,它可能是几种材料体系的复合,以达到性能要求。对于正负极活性材料,我们需要对材料的整体结构,和材料表面进行对应的改性,设计电池和电极的结构。

这是我们认为可以通过原位固态化这样一个标准方法能够实现半固态和全国电池的制造的典型电极结构。中间是隔膜或者固态电解质层,和正负极构成电极结构。这是我们认为在当前固液混合阶段里面,哪些工序会有一些新的变化。结合固液混合的特点,首先材料体系会有一些新的调整。刚才谈到我对正负极的,对固态电解质的,甚至对隔膜和固态电解质膜的性能的改进,那么新材料导入之后,对分散、匀浆和极片制造的工艺就会产生新的变化。新引入的固态电解质膜,也会跟以前的隔膜和涂层隔膜有很多不同。在化成阶段里,如何通过原位聚合如引入电解液,如何实现原位固态化,这个新的工艺会提出新的挑战。

卫蓝经过两三年的开发,我们已经实现了300Wh/Kg的电池,它能够实现比较好的循环性能,尤其是45℃高温循环寿命能够超过1000圈。同时,它可以在如此高的能量密度条件下,通过针刺测试。对于硫化物体系,它也有对应的湿法和干法工艺,可以导入其他诸如烘干、压片等工序。相比现在的工艺过程还会更复杂一些。如果采用干法工艺,那么固态电解质层的导入及其加工工艺会更加复杂。新的工艺会不断涌现,工艺的开发和验证还有比较多的工作去开展。

这是今年四月份报道的三星全固态电池,质量能量密度达到400Wh/Kg,体积能量密度达到900Wh/L。这个电池从综合指标来讲,处于全球先进水平。但是这个产品涉及很多工艺问题,包括热等静压技术,干法制备电极技术,压缩转印技术等相关技术适不适合大规模生产,如何从实验室走出来,这里还需要很多工艺方面的考虑,装备的开发以及如何实现稳定的,一致性较高的生产。对于聚合物电池,同样也分为湿法和干法工艺两种,这是大家能够通过行业或者领域的进展能看得到的。

固态电池提供了比较好的前景,可以采用内串联结构。这种结构对电池从单体到模组的集成提供了更好的解决办法。电芯结构可以采用多层制备的方法,极片更加致密,对于体积能量密度会有比较大的提升。新的叠片工艺在未来的固态电池领域,会得到更大的应用。为什么这么讲呢,根据我们应用的主要电极结构,在电池的充放电过程中,卷绕或叠片各有特点。大家会更深入地分析哪种结构更适合高膨胀率的硅碳负极或者其他新负极的导入。

从电芯的包装形式以及结构来讲,随着固态电池技术的发展,也会有新的变化。由于固态电池可以提供更宽的工作温度范围,固态电池的安全设计要求会进一步简化。对箱体以及对模组的效率呢也可以进一步提升。确实B公司和C公司在这方面做了很多很好的工作,如果固态电池按照这样的方式去设计,我相信也会把能量密度进一步提高到更高的水平。我们做个简单的测算,如果300Wh/Kg的电池采用CTP的形式成组,那么它的成组效率有可能达到75%。如果采用刀片电池结构,可能会达到80%以上。如果我们能够简化冷却系统,那么成组效率有可能达到85%以上。但这里面还有很多的开发和验证工作。这是在成组工艺上,因为结构的简化和制程的简化,那么有可能让我们在模组成型这个工艺中得到流程简化,进一步降低成本。

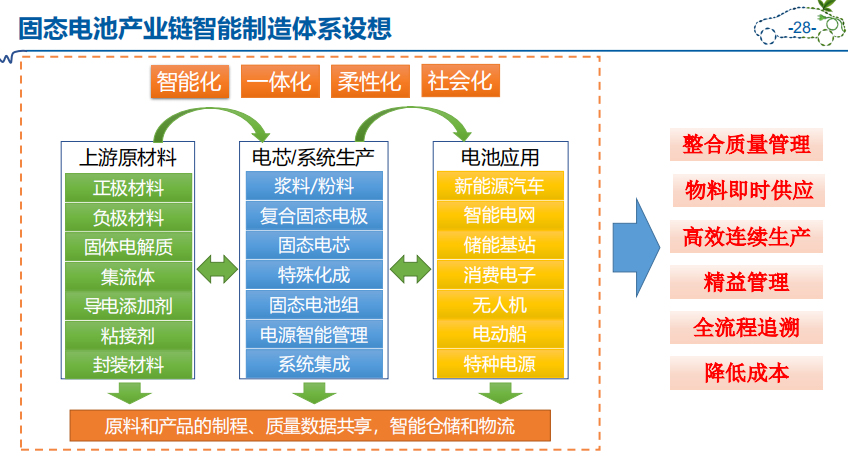

电池系统因为它的高集成度,对于未来的智能化管理和无线通讯,在模组方面也会得到更大范围的应用。那么我们下面来看一下,固态电池系统和产业发展对智能制造有什么样的需求。前面我们也看到先进电池技术的发展,已经把这个产业推进到千亿级,很快会进入万亿的规模。那么固态电池的发展应该在一个更高的起点上,全面地考虑这个产业如何去构造。固态电池产业的发展应该从上游原材料,甚至在上述电池材料的原材料,如何通过信息化,数字化,智能化来管控整个体系。材料的组织制程、MES导入和智能工厂已经做起来了。在电池行业,它应该成为新建的动力工厂正在普遍应用的技术。在业务端,如果我们把电池技术和相关的物料信息,生产制造信息,质量信息,物流信息,能够为下游的客户形成很好的链接,对于下游客户的支撑将发挥很好的作用。同样,作为电池行业,对于上游材料的要求,如果也能建立智能制造的生态系统,那么对于这个行业发展会起到积极的推动作用。这里主要涉及原料和产品的制程,生产制造的质量数据,以及智能仓储和物流。最终整合质量管理、物料即时供应,实现高效的连续生产,把敬意管理、全流程和降低成本跟整个生产流程结合起来。

固态电池也好,其他新型电池也好,在有了比较好的材料体系设计和结构设计之后,要通过工艺把它做起来。那么每个工艺必须分析工艺目标,以及需要什么样的工艺条件和什么样的工艺装备去支撑这个方面去发展。我们简单举几个例子,比如说在固态电池领域,未来有可能应用的,比如电极干法混料技术。对于这个工艺因素的分析,就需要在研发过程和开发过程里面去落实。比如干电极技术,也可能导入进来。比如热复合技术,需要结合电池的制程,以及过程和最终的性能要去开发和落实。

未来能不能基于历史数据,通过机器学习、数字仿真和优化,再加上策略控制系统把AI的相关技术跟整个生产和装备比较好地结合起来,然后通过数字虚拟涂布机完成闭环的不断优化,最终的目标是实现我们在生产过程里面对单工序的智能化控制和智能化管理。这样对单工序的PPK和智能制程能力会有大的提升。我在这里举一个例子,这是卫蓝基于西门子的平台与天目湖研究院合作打造了一个智能工厂的MES控制系统。这个系统和其他公司的系统有一些不同,除了正常的生产计划、过程管理和质量管理以外,它对安全管理,对能源消耗,对成本,对基于工厂层面的整个信息化管理也都明确地提出来了。包括我们刚才讲到的单工序的智能化研发,这个工作现在已经启动,有一些比较好的结果。

这是数字孪生的车间主要系统,刚才方志刚先生已经讲过了,我就不做具体介绍了。那么从我们整体的研发体系以及未来的产业发展上,我们希望能够从研发阶段构建以数字化为基础,让实验试制和数字化的模拟仿真比较好地结合起来。在制造环节输出产品设计之后,能够在制造环节通过MES和DTW与客户的信息交互形成一个良性的互动。另外,站在整个行业的产业链和电池产品的全生命周期管理的角度,形成全闭环的产品信息的追溯和数字共享。在未来,随着半固态电池和全固态电池的发展,我们相信会从目前的现有装备占据80%左右,慢慢过渡到未来的大约80%的新技术和新工艺会导入固态电池产业。那么这个目标还需要数字化和智能化技术起到非常强的支撑作用。同时结合先进测试和失效分析技术,最终达到下一代工业4.0锂电池产业链的发展方向。未来我们会面向更高能量密度、更安全、更强的续航里程,更好地面向应用场景去开发我们的工作。